“The Industry Got What It Asked For” – Partek's Hagen Schulz on U.S. Skiing’s Lift Affordability Crisis

Could a chairlift co-op help modernize America’s aging lift fleet?

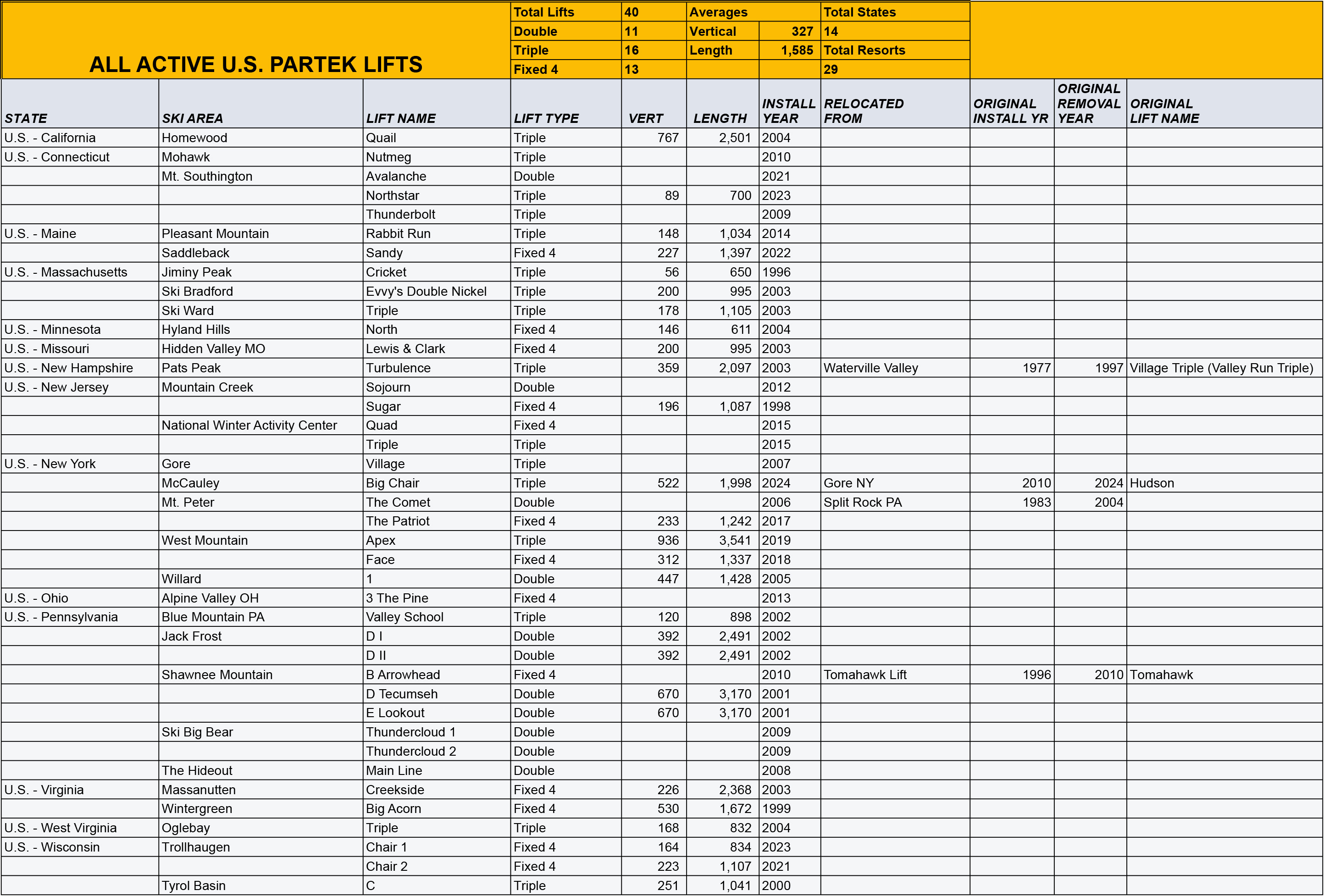

Hagen Schulz has been building chairlifts since 1981, first for the Borvig lifts company, run by his father, Gary Schulz, and then under the banner of Partek, a company that he founded in 1996. Over the past three decades, Partek has built 40 fixed-grip chairlifts at 29 U.S. ski areas in 14 states:

Everyone loves working with Hagen. Jim Rochford Jr., second-generation owner of Trollhaugen, Wisconsin, told me on the podcast that “working with [Hagen] was spectacular,” when I asked, in 2023, why he’d purchased a second fixed-grip quad from Partek in two years. “The support you get from your manufacturer is huge,” Rochford said, “and if I give those guys a call, I’m calling a guy’s cellphone – the guy who is the owner of the company, and he’s the one who answers, and he’s the one who’s got the answers.”

Saddleback, Maine GM Jim Quimby related a similar story behind the replacement of their short Sandy fixed-grip quad in 2022. “Hagen held to a price he offered three years ago, which was about half of the price of a lift that we could have gotten from another manufacturer, which wouldn’t have been available anyway,” Quimby said on the podcast in 2023. “He built it, he helped us install it. He sees the installation through.”

The formula behind Partek’s lower cost, Quimby said, was a small crew, combined with the fact that it is “a very basic lift.” Sandy, which replaced a falling-apart 1967 Hopkins double, is “sturdy. It’s well-built. It was easy to build. It was well-manufactured, but you can use off-the-shelf parts to fix it.”

But Hagen built his last new lifts in 2023 – the Trollhaugen quad, to serve an expansion, and the Northstar triple chair at Mount Southington. With the exception of an occasional outlier such as Waterville Valley, which contracted France-based MND to build its Tecumseh six-pack in 2022, Partek’s exit from new construction projects leaves U.S. ski areas with the choice of two large manufacturers, both of which are subsidiaries of European lift companies: Doppelmayr and Leitner-Poma. The latter also owns fixed-grip chairlift specialist Skytrac.

Hagen thinks the U.S. ski industry could be headed for catastrophe without major changes to the way that chairlifts are sold, built, and serviced. The landscape has many problems, most of which can be summarized in this way: small, independent ski areas are unlikely to be able to afford new chairlifts as their legacy machines reach the end of their useful life and the supply of re-usable machines from larger ski areas dries up.

“Midwestern ski areas and small and mid-sized ski areas in the Northeast, definitely in the next five to 10 years, maybe sooner, are going to be in a very bad spot with some of the equipment they have as far as retaining parts,” Hagen told me in an hourlong October interview.

Even though plenty of Borvig, Hall, Riblet, and Yan lifts remain, parts are becoming scarce, along with independent contractors with the knowhow to repair the lifts, Hagen says. “The problem on the service side is that there aren’t that many people left that are independent of the two big manufacturers.”

Hagen blames the ski areas themselves, telling me that “the industry got what it asked for,” by bidding smaller shops like Partek against European-backed giants Doppelmayr and Leitner-Poma. But Hagen believes there is a way for ski areas to modernize and build new lifts: he told me that if several dozen ski areas formed a cooperative that builds simple chairlifts, and committed to purchasing any future lifts from this operation, they could assure a supply of simple, easy-to-maintain machines for generations. But it will be up to ski area operators themselves, Hagen says, to organize around the idea before it’s too late.

Here are excerpts from our conversation, the latest story in a series exploring the state of America’s aging lift fleet. You can read the first part here:

Everything other than the section headers below is a direct quote from Hagen, though I’ve edited the text for length and clarity.

HAGEN ON BUILDING LIFTS THEN VS. NOW

“We need to go back to the 60s and 70s, when a lot of smaller areas were built. These were not developers or big corporations. They were small mom and pops, farmers with 40 acres and a hill, and they used their own capital very resourcefully. They built everything themselves. They engineered homemade snowmaking systems, and when it came to lifts, they had a lot of options.

“In the 60s and 70s, a lot of lifts were bought as erector sets. The operator received a pile of material and they welded ladders on in the field. Wood slats for chairlifts came piled on a pallet. Towers were delivered with one coat of primer paint. That was the market back then. No one had money. Everyone put things together themselves.

“Now we’re dealing in a market where almost everyone wants a turnkey operation. The dirtiest someone wants to get in the process of buying a lift is when they touch ink to sign the contract.